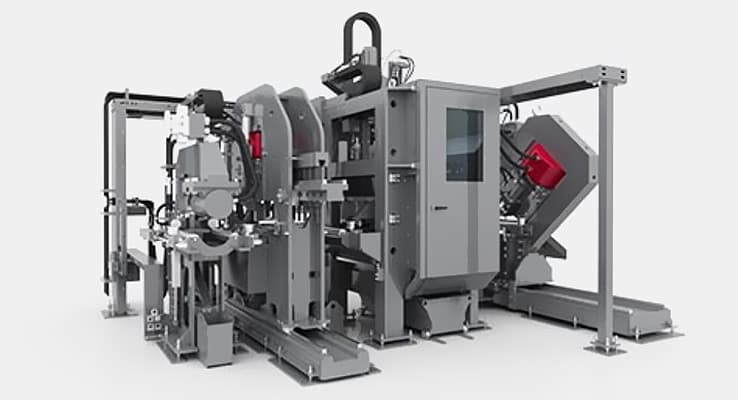

Beam Layout Welding 12 Gauge

Pre-Engineered Buildings is a shorthand for Pre-Engineered Buildings. This basically means that parts of the machine have been built and manufactured before they are assembled. Many people mistakenly believe that an H beam looks the same as an I beam. They are very different in reality!

.jpg)